Recently a czimages visitor sent me some really great French Era photos of which several were French dredges. The photos are very nice and sparked

an interest in me to do a bit of research to learn more about the great old machines. The article below I took from an old Scientific American publication,

Supplement No. 476, dated February 14, 1885. This article is written in the style of the day back then, and may seem strange in some parts, but the

information within is most valuable.

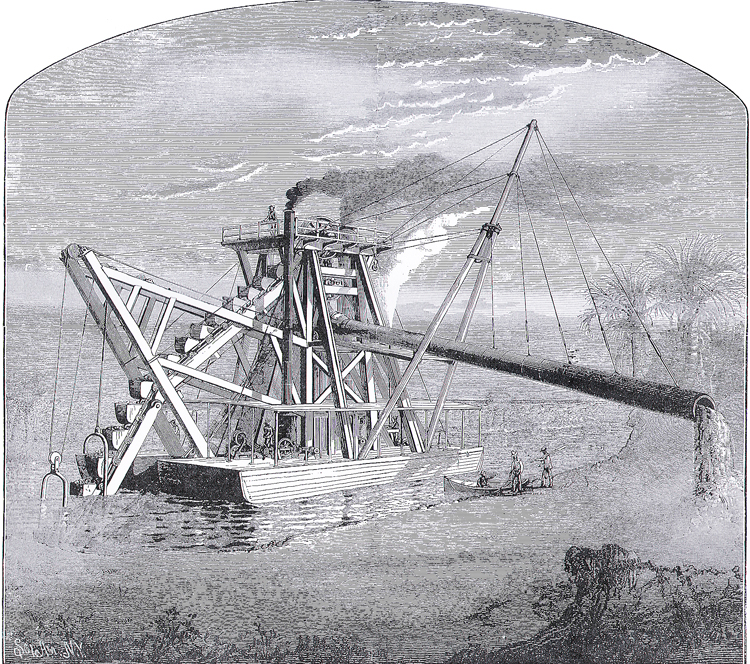

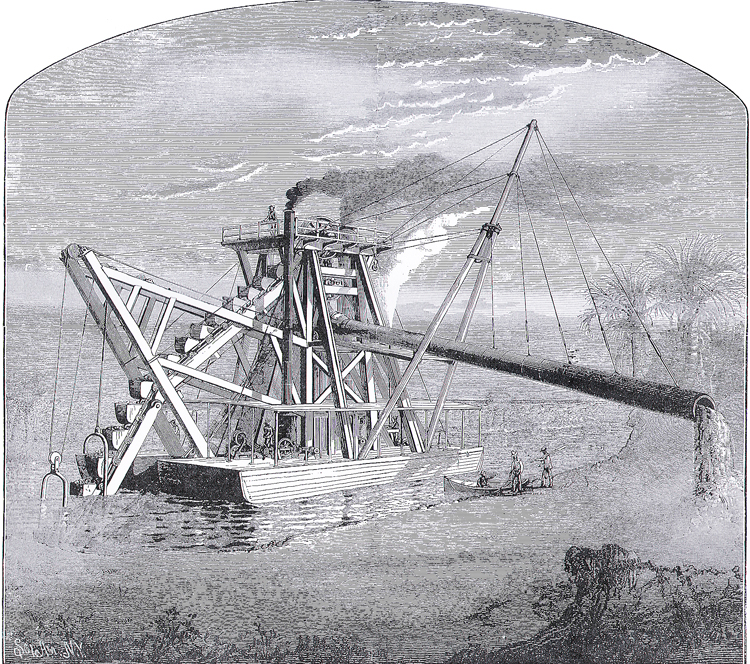

The author/s are speaking of a new dredge used by the contractors known as the Slaven Brothers which evidently was a far superior dredge than the Suez type

dredges that the French started out with in Panama. (See article following the Scientific American article below.) Above is an old engraving of the Slaven

Dredge at work in Panama. This excellent engraving accompanied the article

below it.

With all this being said, starting next week I will begin posting these recent new images that were sent to me. This will begin a mini-series for the

next few weeks about the dredgers of the French.

THE AMERICAN DREDGERS ON THE PANAMA CANAL.

Our engraving represents one of the great dredgers now in use on the Panama Canal. The contract for the ten miles of marsh work, beginning near

Aspinwall, taken by Slaven Brothers, this city; the great machine is believed to be the most effective of anything in the line. It was built under

the patents of Messrs. H. B. Angell and H. H. Lynch. The machinery of the dredge is mounted on a scow one hundred feet long, sixty feet wide, and

twelve feet deep. There are eight engines, arranged in four pairs, for operating the machinery. The main engines are for driving the buckets which

do the digging, and are of 250 horse power, having Myer’s adjustable cut-off. The belt from the engine runs to the top of the bucket tower to a

pulley eight feet in diameter, which drives compound driving gear, connected with the upper tumbler shaft, which is ten inches in diameter. This

shaft moves a thirty-six inch square drum, over which the buckets pass when they dump their load into the hopper. The bucket tower IS forty-five

feet high above deck. There are thirty-eight buckets, with a capacity of one and a half cubic yards each. From sixteen to eighteen buckets full of

dirt per minute are discharged into a hopper attached to a cast iron elbow near the top of the tower. This elbow is five feet four inches in diameter

where it connects with the hopper, and thirty-six inches in diameter where it connects at the lower end to the discharge pipe, which is attached to

the elbow. This pipe is made of boiler iron and is one hundred and fifty feet long. The distance the mud falls, the position in which it strikes, and

the inclination of the discharge pipe give the mud a velocity of from 1,300 to 2,000 feet per minute through the pipe,

according to the kind of material which is being dug and discharged. The discharge pipe is supported by a derrick which stands on the scow. Water is pumped into the hopper by a pair of

ten inch pumps from the canal through a seven inch pipe which passes through the bottom of the boat and extends to the hopper, at top of bucket tower.

A second pair of engines of thirty horse power raise and lower the ladder that supports the buckets; they are attached to a drum for that

purpose. There is a hinged joint in the ladder outside of the derrick, for the purpose of operating one section of ladder independent of the other. A half inch cable

connects the drum to the outward end of the lower section by two bails. The endless chain to which the buckets are attached is made of horseshoe iron

1 1/8 inches by 9 inches. Another pair of spud and gypsy engines of thirty horse power is used for raising the spuds and feeding the buckets. The dredger

rests upon the spud, upon which it can be revolved without stopping the dredging buckets, thus enabling the operators to dig from side to side at will.

A chute connects with the hopper, and is boarded on the sides to prevent the mud or water from falling upon the deck. The fourth pair of engines, also

of thirty horse power, is connected to a windlass for snag pulling. The engines are all supplied with steam from one set of three boilers, and will

require only about two tons of coal each day. Six men, including a superintendent, run the entire machine. Capacity of the dredger, 1,000 cubic yards

per hour.

The cutting of the canal is to be 100 feet wide at the bottom, 185 feet at the top and 27 ½ feet deep.

A correspondent of one of our city papers, resident in, New York, who just returned from a visit to the works of the Panama Canal, writes:

The canal is an assured fact. The French seem thoroughly to understand the work before them, and have made admirable preparations to cover all contingencies.

The take the greatest care of their employees, and their hospital service is unsurpassed in the world. A force of over twenty thousand men is a good many to

handle, and, of course, entails a lot of red tape, but that seems necessary, especially with Frenchmen. But they have a grand chief in M. De Lesseps, and

have now a splendid working staff in M. Diggler and his officers.

I was very anxious to see the Scotch dredger at work in the harbor of Colon, but it was not in operation during the eighteen days I was there. I was disappointed, as I wished to compare it with our mammoth American

dredgers. It cost, I understand, £50,000, and is considered very good for deep-sea dredging, but for actual work I saw nothing there to compare to our American dredgers. I went on

board and saw the latter work on many different occasions, and was highly satisfied. The principle is unique and very ingenious. The tower is iron, 75 feet high;

the buckets and chains, are of, steel, and each bucket will, and does .take 1 ½ tons of earth each lift. The spud, on which the dredge rests and

revolves, enables It to take a sweep of 15 meters wide, and each move of the spud moves her forward 18, feet, so that, like a mowing machine, she cuts a swathe (to use a farmer's

expression) 45 feet wide, 18 feet long, and 9 feet deep, on each movement forward. They work perfectly, and it is indeed a grand sight to sit, as I have done, for

an hour or two at a time, and watch them working. Rotten coral, roots, stumps of small trees, etc., all come up with the dirt, and make no difference. Of course,

where rock is struck, or hard coral, or an old petrified monarch of the forest, blasting has to be done by the canal company ahead of us. Otherwise, after the ground

is cleared of vegetation, trees, etc., we simply start in and eat--literally eat-our way through with absolutely no other preparation whatever, no men on shore working

ahead or any other way. What we take out goes though the dredger's own discharge pipe on to the bank, and forms practically the bank of the canal proper. We have now cut

from the sea (the harbor of Colon) three and a half miles of the canal by one machine, and some ten miles up we have two other

machines entering from the Chagres River, cutting their way back to meet the first machine. A fourth machine leaves here tomorrow, and will join the others by the middle of January, while eleven more are

building, and will follow, one each six weeks or so, until all are fairly at work. Our contract is for 30 million cubic

meters, and will probably lead to half as much again, as it is conceded by the canal company and everyone in the isthmus that nothing like our machines has been seen: or used anywhere. One instance of their capacity

I saw myself. A Suez dredger was put to work at a certain spot. After fifty days she was withdrawn, and one of ours took its place, and did in five days as much as the

other had done. Our machines cost about $125,000 (say £25,000), and require about 20 men to work them.

Slaven Brothers - Contractors

SLAVEN, HENRY BARTHOLOMEW, distinguished capitalist and financier, and the practical constructor of the large completed section of the Panama Canal, was

born in Picton, Ontario, October 19, 1853, the son of Patrick Slaven, a successful stock raiser. He at tended the common schools up to the age of ten,

and then, entering. a drug store as clerk, attended an evening school. At the age of seventeen he was graduated from the Ontario College of Pharmacy, and

spent the next two years as a student at a Philadelphia medical college. He then accepted a good position in a large wholesale and retail drug establishment

in Philadelphia, and later returned to Canada to assume the active management of a large wholesale drug house in the Dominion. He remained in the successful

direction of this business from 1873 to 1876, and then resigned with the view of establishing himself in the far West.

His brother, M. A. Slaven, had become a successful contractor in California, and this fact was probably a determining factor in turning Mr. Slaven’s eyes

toward the section where his great enterprises were to have their origin. In 1876 he accompanied a party of engineers through the then unexplored country,

by way of the Great Lakes, to the present Port Arthur, thence to Winnipeg, Manitoba, and thence westward through Manitoba and the British Northwest. The tour

was successfully accomplished, notwithstanding the presence of hostile Indians. At its conclusion Mr. Slaven proceeded to St. Paul, Minnesota, and thence to

San Francisco. In the latter city he established a drug and manufacturing business, and such was his mastery of this line of business, and his general executive

and financing abilities, that in a short time he developed his enterprise into the largest establishment of the kind on the Pacific coast. He also be came

interested with his brother in contracting enterprises, and it was a signal tribute to this firm that in 1878 the Slaven Brothers should be selected by De Lesseps

and contracted with to assume the control and execution of all the Pacific coast operations in connection with his gigantic enterprise, as well as to do all the

preliminary work, including the erection of the buildings at the Isthmus of Panama.

In 1880 Mr. Slaven went to the Isthmus in person to inaugurate the work, taking with him two steamers, loaded with men, provisions, and the materials of construction.

Finding the men largely incapacitated by malaria, he inaugurated the policy of employing native labor, and was thus enabled to successfully execute his contracts.

In 1882 the brothers closed a contract for the actual construction of the Atlantic division of the canal, a section sixteen miles long, from Aspinwall to Bohio

Soldado. Their contract involved the ambitious project of changing the course of the Chagres River for the same distance. To organize this construction enterprise the brothers

removed their headquarters to New York City, and in September, 1882, they secured the incorporation of the American Contracting and Dredging Company. Of this corporation

Mr. Slaven was President, the late Eugene Kelly Treasurer, M. A. Slaven General Manager, and James J. Plielan Secretary. The shares of the company rose from $30 to over

$400; and well they might, for upon the completion of the contract for the construction of the Atlantic division of the canal, in 1889, Mr. Slaven’s company was paid

$25,000,000 by the De Lesseps Company.

The work of construction, in progress from the fall of 1882 to 1889, was an interesting performance among enterprises of the kind. For its execution eight gigantic dredges

were devised, the largest in the world, and costing $150,000 each.. This model was known as the” Slaven dredge.” During the period of construction, Mr. Slaven was at the

Isthmus most of the time, personally superintending the work. In 1889 the American Contracting and Dredging Company was about to be awarded a further contract for the completion

of the canal, when the collapse of De Lesseps’s French company occurred. “Had the other interests in connection with the project been handled as skillfully and judiciously as the

part operated by Mr. Slaven,” re marks the writer of an article in the well-known work published by the New York Tribune, “the canal would have been carried to a successful

completion and have resulted in revolutionizing the ship ping and commercial interests of many

countries.

Leslie's History of the Greater New York: Biographical: Volume DeLuxe

by Daniel Van Pelt. Arkell Publishing Co., New York.1898.