Continuing with the same collection of old photos taken in Gatun during the construction days and featuring people at work and play.

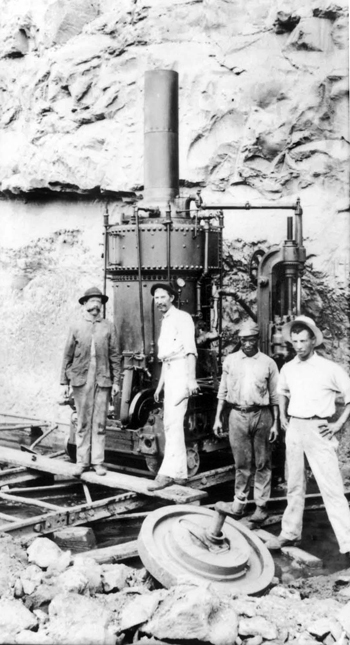

This week's photo is photo titled "A Sullivan Channeler in Lock Site Gatun".

Channelers were extensively used during the construction of the

Panama Canal where precision cutting was needed vs. the drilling and

blasting of rock. This is a great photo of one such channeler

and it's crew in what would eventually become a chamber for Gatun

Locks. What a great capture of the crew that ran this

machine. I have found a little history about channelers below:

For hundreds of years, stone was cut from the earth by hand. It was a slow, labor intensive process that limited the size of blocks that could be quarried. Vertical holes were drilled around the block of stone to be removed. At the bottom of the block a row of horizontal holes was drilled. The holes were filled with water and wooden plugs were driven into the holes. As the wooden plugs absorbed the water, they swelled and lifted the block of stone free from the earth. A good worker could drill 25 lineal feet of 12-inch to 24-inch holes in one day. Deeper holes would require three men. Their output was generally 40 to 50 feet per day.

In addition to the drilling method, channeling was practiced in many marble quarries. Through the Civil War, channels were cut by hand simply by swinging steel picks against the stone until the stone was worn away. The greatest depth a channel could be cut was about eight feet. At this depth the channel was only six inches wide, just room enough for the stone cutter to place his foot one in front of the other as he moved forward.

Channel cuts would generally run perpendicular the joints in the stone. Spacing would be set to produce a minimum number of joints in the blocks. Most marble deposits had one system of joints that was prominent with only a few cross joints. Channeling was then done at right angles to the prominent joint system. The joints would then be used to help make the cross breaks. Also, by making the cuts at right angles to the direction of rift or grain, splitting by drilling and wedging was made easier.

Originally operated by a steam boiler, the channeler was soon expanded to have cutting heads on both sides of the track. This allowed the cutting of two channels at once. A further improvement eliminated the steam boiler and

utilized an electric motor. While being limited to only vertical cuts, the cost of operation per square foot of channel cut was dramatically less than manual labor.

Sullivan and Ingersoil soon developed channelers that featured swinging heads that could be tilted to any angle, allowing machine horizontal cuts for the first time. Sullivan channelers used diamond core drills which improved greatly over the hand drills. Diamond prices, however, rose too high to make the drills cost efficient.

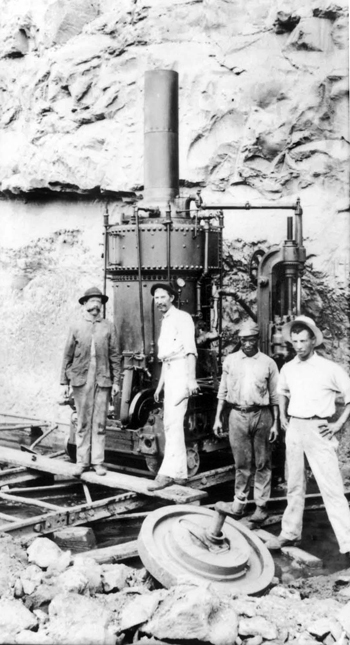

Another great photo from this collection.

I may be moving on to another collection next week as I have pretty

much exhausted the more interesting photos.